STI/SPFA 2023 TANK OF THE YEAR Product Award – Reservoir

| Product /Project Title: | Holly Drive Reservoirs, Phase III |

| Product Owner: | San Antonio Water Company |

| Product Location: | San Antonio Heights, CA |

| Date Completed: | December-2023 |

| Overall Height or Length: | 22’ |

| Diameter (feet/inches): | 32’ |

| Capacity (gallons): | 120,000 |

| Steel Tonnage Used: | 31 |

| Steel Thickness (inches): | 0.25” – 0.3125” |

| Product/Project Description: | |

| This 120,000 gallon welded steel tank features a knuckled self-supporting umbrella roof. The tank is erected next to an existing storage tank with updated seismic and appurtenances, and larger storage capacity while utilizing the existing site to maximum efficiency. | |

STI/SPFA 2023 TANK OF THE YEAR Product Award – Repair and Modification

| Product /Project Title: | Washwater Tank Seismic Improvements |

| Product Owner: | Santa Fe Irrigation District |

| Product Location: | Rancho Santa Fe, CA |

| Date Completed: | January-2023 |

| Overall Height or Length: | 80’ |

| Diameter (feet/inches): | 46’ |

| Capacity (gallons): | 950,000 |

| Steel Tonnage Used: | 25 |

| Steel Thickness (inches): | 1.5″ |

| Product/Project Description: | |

| This project consists of the Seismic Improvements to Washwater Tank. The project included new tank foundation, new anchor chairs, new tank shell stiffeners, repairing existing rafters, new mesh screen to overflow, modifying existing external inlet/outlet piping, provide new gasket to existing roof manway, remove existing center roof vent and install new center roof vent, provide new fall prevention system to existing interior ladder, provide new toe-boards for existing stairway, provide new tether points, and providing new patch plates for holes or pitted areas.

Even though the tank had been in service for 40+ years with no issues, a structural evaluation was done and determined that the foundation was severely undersized. Most contractors bid this job to install piles and pour a matte foundation under the tank in sections with it still in place. But with some careful planning and engineering, we were able to come up with a plan to move the entire tank 200′ off the existing pad. This specific situation is unique due to the fact that this a standpipe opposed to a flatbottom reservoir. No other tank construction has the flexibility or material characteristics to allow this move which exemplifies the beauty of steel. |

|

STI/SPFA 2023 TANK OF THE YEAR Product Award – Shop Fabricated Atmospheric Tank

| Product /Project Title: | Winery Expansion |

| Product Owner: | Presqu’ile Winery |

| Product Location: | Santa Maria, CA |

| Date Completed: | April-2023 |

| Overall Height or Length: | 20’ |

| Diameter (feet/inches): | 10’ |

| Capacity (gallons): | 9,400 |

| Steel Tonnage Used: | 6 |

| Steel Thickness (inches): | 0.135” |

| Product/Project Description: | |

| The project consisted of two double walled and insulated shop-built tanks. The inner tank is 10′-0″ diameter x 16′-0″ high stainless-steel dimple jacketed, truncated roof, flat sloping floor with integral 32″ tall stainless steel stand. The inner tank is insulated with 2″ of polyisocyanurate foam and cladded with an all seal welded 12 ga outer shell that is 10′-5″ diameter x 16′-3″ tall.

These tanks were built from the top down using MIG and TIG welding processes. The dimple jackets on the inner tanks were spot welded and welded around the perimeter to seal the two pieces together. The dimple jacket is then inflated to create a void for the glycol to flow through. This jacketing allows the winery to control the temperature of the wine during fermentation all the way through bottling. These tanks in total hold 18,800 gallons, enough wine to make 7,907 cases of wine or 94,887 bottles of wine. |

|

STI/SPFA 2020 TANK OF THE YEAR Product Award – Reservoir

| Product /Project Title: | Dalton Reservoir Replacement Project |

| Product Owner: | City of Livermore |

| Product Location: | Livermore, CA |

| Date Completed: | May-2020 |

| Overall Height or Length: | 32′-0″ |

| Diameter (feet/inches): | 155′-0″ |

| Capacity (gallons): | 3.5 MG |

| Steel Tonnage Used: | 554 |

| Steel Thickness (inches): | 1″, 3/4″, 5/16″, 3/8″ |

| Product/Project Description: | |

| Project consisted of demolition of an existing 2 MG concrete water storage tank and building a new 3.5 MG potable water storage tank in its place, nearly doubling the City’s capacity at this location. The footprint expanded from an existing 130′ to 155′ in Diameter. As location of the tank was in a cultural and biologically sensitive location, construction was performed under permitted conditions and the watchful eye of both a biologist and Native American monitors to ensure protected species remained unharmed and no artifacts of cultural significant were destroyed. | |

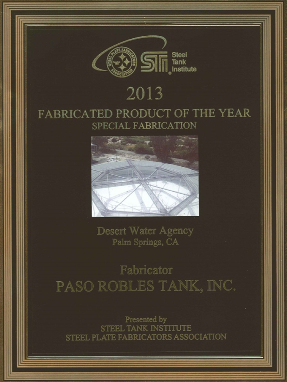

STI/SPFA 2020 TANK OF THE YEAR Product Award – Fabricated

| Product /Project Title: | (18) Wine Storage Tanks |

| Product Owner: | PRIVATE |

| Product Location: | Paso Robles, CA |

| Date Completed: | May 2020 |

| Overall Height or Length: | 17′-9/16″ |

| Column Height: | 14′-0″ |

| Diameter (feet/inches): | 15′-3″ |

| Capacity: | 19,300 |

| Steel Tonnage Used: | 65.09 |

| Steel Thickness (inches): | 0.43″-0.187″ |

| Product/Project Description: | |

| These (18) stainless-steel dimple jacketed, truncated roof, elevated sloping floor tanks were built from the top down using MIG and TIG welding processes. The bottom 12″ of the tanks is a “Skirt” that is filled with concrete to support the elevated sloping floor. The tank is anchored with the latest innovation in seismic anchoring on the market today. The dimple jackets on these tanks are two sheets of stainless-steel spot welded and welded around the perimeter to seal the two pieces together. The dimple jacket is then inflated to create a void between the two sheets for the chilled glycol to flow through the jacket. The dimple jackets is made from 304ss with a #4 finish that gives it that shiny, bright look. These tanks in total hold enough wine to make 149,575 cases of wine or 1,794,900 bottles of wine. |

|

STI/SPFA 2019 TANK OF THE YEAR Product Award – Reservoir

| Product /Project Title: | San Manuel East Reservation Water Storage Reservoir |

| Product Owner: | San Manuel Band of Mission Indians |

| Product Location: | Highland, CA |

| Date Completed: | Dec-19 |

| Construction Standard: | AWWA D100 (Steel Storage Tank Manual & Standards Set (awwa.org)) |

| Overall Height or Length: | 32′-0″ |

| Column Height: | 35′-11 1/16″ (3 columns) |

| Diameter (feet/inches): | 80′-0″ |

| Capacity: | 1.1 MG |

| Steel Tonnage Used: | 181.2 |

| Steel Thickness (inches): | 7/16″, 1/4″ |

| Product/Project Description: | |

| 80 foot diameter x 32 foot high External Press-Broke Knuckle Roof tank. Close proximity to major fault lines in Southern California, this tank was engineered with a (3) column open center support structure and an external press-broke roof. With that combination, the roof is able to accept a 7 foot sloshing wave during a major seismic event without failure. In addition, the fully seal welded Press-Broke structure allows for ZERO inaccessible areas on the interior of the tank in the crucial vapor space, so opportunities for potential corrosion are dramatically decreased and this tank should see extended service life’s in between maintenance cycles. | |

STI/SPFA 2019 TANK OF THE YEAR Product Award – API 650 Atmospheric Tank

| Product /Project Title: | API 650 Thick Juice Storage Tank |

| Product Owner: | PRIVATE |

| Product Location: | Twin Falls, ID |

| Date Completed: | August 2019 |

| Construction Standard: | API 650 |

| Overall Height or Length: | 48′-0″ |

| Column Height: | 46′-6″ |

| Diameter (feet/inches): | 146′-0″ |

| Capacity: | 5,800,000 |

| Steel Tonnage Used: | 467 |

| Steel Thickness (inches): | 0.938″ |

| Product/Project Description: | |

| This emergency project was brought to us at the end of an extraordinary harvest which left our client faced with the decision to waste product or build additional storage. Of course this wasn’t going to be at an ideal time of the year and tank erection had to be completed in the middle of winter months. But when others said it couldn’t be done we stepped up and designed, fabricated, and installed a 5.8 million gallon tank in less than 4 months! The design temerpature was 100 degrees Fahrenheit and the design metal temperature (DMT) for the site was -3 degrees Fahrenheit. This temperature variation required the use of custom steel which was impact tested prior to use. |

|

STI/SPFA 2019 TANK OF THE YEAR Product Award – Special Storage

| Product /Project Title: | (4) Fermentation Wine Tanks (2) 24′-0″ Dia. x 36′-0″ High (2) 24′-0″ Dia. x 28′-0″ High |

| Product Owner: | PRIVATE |

| Product Location: | Dundee, OR |

| Date Completed: | Oct 2019 |

| Construction Standard: | |

| Overall Height or Length: | 38′-8″ |

| Column Height: | 36′-0″ |

| Diameter (feet/inches): | 24′-0″ |

| Capacity: | 122,347 (for 36′ high tanks) |

| Steel Tonnage Used: | 11.396 (Total) |

| Steel Thickness (inches): | 0.105″-0.187″ |

| Product/Project Description: | |

| These 4 Tanks are stainless steel dimple jacketed, conical roof, flat sloping floor tanks were built from the top down using mig and tig welding processes. The dimple jackets on these tanks were spot welded and welded around the perimeter to seal the two pieces together. Thedimple jacket is then inflated to create a void for the chilled glycol to flow so the wine could be cooled. The base stainless steel is made from 304ss with a 2B finish, the dimpla jacket is made from 304ss that has a 4b finish and fives it that shiny, bright look. These tanks in total hold enough wine to make 182,235 cases of wine or 2,186,820 bottles of wine. | |

STI/SPFA 2018 TANK OF THE YEAR Product Award – Reservoir

| Product / project title: | Jamestown Reservoir Replacement Project |

| Product / project owner: | Tuolumne Utilities District |

| Product / project location: | Jamestown, CA |

| Date completed: | Nov 2018 |

| Construction standard (if any): | AWWA Section 14 |

| Overall height / length (feet, inches): | 32’ -2” |

| Column height (feet, inches): | 28” -7” |

| Diameter (feet, inches): | 75’ – 0” |

| Capacity (US gallons): | 1,000,000 |

| Steel tonnage used (US tons): | 139 |

| Steel thickness (inches): | 0.250” |

| PRODUCT/PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| Project consisted of design, procurement, fabrication and erection of a new welded steel tank with foundation and coatings. Previously the district had many issues with the faying surfaces in the vapor space of their tanks so they had extreme concern with mitigating future corrosion. Therefore the bid required a competent contractor which could successfully design a reservoir to prevent the future corrosion with an innovative design. The district had previously seen the benefits of utilizing our design on steel tank roofs because they replaced a roof with an external press brake system the previous year and have been nothing but satisfied with its results. If it wasn’t for steel’s unique characteristics and ability to be shaped / formed this roofing system would not be possible. |

|

STI/SPFA 2017 TANK OF THE YEAR Product Award – Reservoir

| Product / project title: | Paradise Meadows 5.0 MG Tank |

| Product / project owner: | Eastern Municipal Water District |

| Product / project location: | Menifee, CA |

| Date completed: | Oct 2017 |

| Construction standard (if any): | AWWA D100 |

| Overall height / length (feet, inches): | 40’ -0” |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 157’ – 0” |

| Capacity (US gallons): | 5,400,000 |

| Steel tonnage used (US tons): | 545 |

| Steel thickness (inches): | 0.25” to 0.78” |

| PRODUCT/PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| The work construction of a 5.0 MG Potable Water Storage Tank and appurtenances including but not limited to the following: furnishing, delivery and erecting a 5.0 MG welded steel tank and appurtenances; all precise grading and construction of the tank pad, detention basin and access road; including 18-inch dia. Detention basin drain pipe and riser; furnishing, delivery and installation of 24-inch dia. welded steel (CML/C) water pipeline and appurtenances; including all welded joints, valves, blowoffs, and air valves; connections to existing water mains with valves and associated removals as needed; trench sheeting, shoring and bracing per California Labor Code; pavement and PCC curb and gutter; valve enclosure; electrical panel and SCE service panels/conduits; all electrical and SCADA equipment; implementation of the mitigation measures identified from the Mitigation Monitoring and Reporting Program; comply with SCAQMD Rule 403 to actively prevent, reduce or mitigate fugitive dust emissions; chain link fencing and gates; painting and coating; all system shutdowns and piping tie-ins; hydrotesting, miscellaneous testing, chlorination/disinfection and field start-up and testing.

This 5.4 million gallon tank was built at 157’ diameter by 40’ tall, with a knuckle roof, and overlooks the new housing development of Audie Murphy, but can be seen from surrounding communities to the west. One of the unique things about this tank is that, when you’re looking for it from the east end of town, it is painted to blend in with the hillside that it was built into, so you really have to scan to find it. In order to make room for this site footprint, and to set the tank at the proper elevation, over 25,000 cubic yards of dirt /rock had to be blasted and removed. As a customer preference the reservoir was designed with a modified structure to support the large roof platform as the additional weight required rafters, poles and a girder to be increased in thickness. Along with their preferred platform design, this customer is extremely particular about operator safety, so they design all of their tanks to have 360 degree handrail, roof tie off cables, and fall resistant grading shields, located on all roof access hatches. As you can see in the picture, the tank is fitted with 5 custom aluminum roof vents, which really standout against the dark color of the tank and hillside. |

|

STI/SPFA 2017 TANK OF THE YEAR Product Award – Reservoir

| Product / project title: | Reservoir 4606-1 Construction (Mission Hills Pressure Zone) |

| Product / project owner: | Coachella Valley Water District |

| Product / project location: | Coachella Valley, CA |

| Date completed: | Nov 2017 |

| Construction standard (if any): | AWWA D100 |

| Overall height / length (feet, inches): | 40’ -0” |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 186’ – 0” |

| Capacity (US gallons): | 6,800,000 |

| Steel tonnage used (US tons): | 619 |

| Steel thickness (inches): | 0.3125” to 0.9788” |

| PRODUCT/PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| This tank was under consideration to be built via concrete or welded but the design team performed a Life cycle cost analysis and overall bid the job as a welded steel tank. It was designed to meet the new demands of an ever growing city as well as supplement future demand of additional housing tracks. This asset will be a critical part of their system for decades/ centuries to come. The tank was designed in accordance with AWWA D-100 section 14 in order to be as cost effective as possible; but due to high seismic load’s and the tank being located just feet away from the San Andres Fault line there were many precautions taken in the design/supply of the reservoir. The tank as a whole weighed more than 1.2 million pounds and was constructed during the Santa Ana winds. The effects of the high winds were amplified by the fact that it’s located on a mountain range which regularly sees winds in excess of 60 mph on any given day. Although there were many days which the crew had to work split shifts or submit a weather delay, we were still able to complete the job on time with a satisfied customer and a safe crew. This was due to the construction sequencing of a welded steel tank and the ability to start / stop as needed in order for the crew to safely follow all applicable safety regulations. |

|

STI/SPFA 2016 TANK OF THE YEAR Product Award – Shop Fabricated Atmospheric Tanks

| Product / project title: | (3) Tanks – 2016 Winery Tank Expansion |

| Product / project owner: | PRIVATE |

| Product / project location: | Charlottesville, VA |

| Date completed: | June 2016 |

| Construction standard (if any): | – |

| Overall height / length (feet, inches): | 20’ -0” |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 11’ -3” |

| Capacity (US gallons): | 15,000 Each and 45,000 Total |

| Steel tonnage used (US tons): | 15 |

| Steel thickness (inches): | 10 ga, 12 ga, 14 ga. |

| PRODUCT/PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| The winery expansion required (3) jacketed insulated tanks with integral dimpled thermal cooling transfer panels on the primary tank shell. This configuration with stainless steel insulation jacket makes steel the material of choice as it affords significant increase in durability and protection of the insulation over conventional PVC jackets. Special shipping fixtures were required, but the 14 ga. insulation jacket is durable enough to survive the cross country shipment without damage. |

|

STI/SPFA 2016 TANK OF THE YEAR Product Award – Reservoir

| Product / project title: | Christen Hill Reservoir |

| Product / project owner: | North Coast County Water District |

| Product / project location: | Pacifica, CA |

| Date completed: | October 2016 |

| Construction standard (if any): | AWWA D100, Sec. 14 |

| Overall height / length (feet, inches): | 67’ -0” |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 108’ – 0” |

| Capacity (US gallons): | 3,750,000 |

| Steel tonnage used (US tons): | 365 |

| Steel thickness (inches): | 1/4” to 15/16” |

| PRODUCT / PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| This project was a challenge to erect and paint due to its hilltop location in a high wind region, but the most significant aspect of this project is the specification implement by the water district to mitigate future corrosion problems in the tank roof. Instead of utilizing minimum requirements of the AWWA D100 standard which results in inaccessible areas in the tank roof structure, the water district specified that all roof laps must be sealed and additionally that the supporting rafters must also be seal welded to the roof plates. In lieu of conventional construction, the tank manufacturer designed a structure utilizing single-span, integral formed structural roof panels for the roof system. This design reduced the required welding by approximately 50% thereby reducing the magnitude of weld shrinkage distortion to be accommodate by the erection methods. With the fully seal welded roof system, the roof and integral structure were easily coated and will be easy to maintain for many decades into the future. The strength and flexibility of steel are exemplified in this project by the ability to produce the single span roof panels at the minimum specified thickness of 1/4″. By utilizing this approach of specifying above the minimum D100 requirements for the tank roof system, this tank has just begun its journey to membership in the highly respected STI/SPFA Century Club. |

|

STI/SPFA 2015 TANK OF THE YEAR Product Award – Reservoir

| Product / project title: | Eastside Water Treatment Facility (2) Reservoir Tanks |

| Product / project owner: | City of Chino |

| Product / project location: | Chino, CA |

| Date completed: | October 2015 |

| Construction standard (if any): | AWWA D100 |

| Overall height / length (feet, inches): | – |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 64’ to 170’ |

| Capacity (US gallons): | (1) 4,000,000 and (1) 500,000 |

| Steel tonnage used (US tons): | 460 Total |

| Steel thickness (inches): | 3/16” to 1/2” |

| PRODUCT / PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| 4.0 million gallon reservoir 170′ Dia. x 27′ High, knuckle roof tank 0.500 million gallon reservoir Murals were applied to these both of these tanks. |

|

STI/SPFA 2015 TANK OF THE YEAR Product Award – API 650 Oil Storage Tank

| Product / project title: | 7157 Digester Gas Storage Replacement |

| Product / project owner: | City of San Jose |

| Product / project location: | San Jose, CA |

| Date completed: | October 2015 |

| Construction standard (if any): | API 650 |

| Overall height / length (feet, inches): | 42’ -8” |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 50’ -0” |

| Capacity (US gallons): | See Below |

| Steel tonnage used (US tons): | 70 |

| Steel thickness (inches): | 1/4” |

| PRODUCT / PROJECT DESCRIPTION AND SPECIAL FEATURES: | |

| This 50,000 cu. Ft. Low pressure gas holder was a replacement to a smaller unit at the facility. The treatment plant needed increased capacity with limited space, and so had to install this new gas holder in the same area originally occupied by the older unit. This unit provides necessary capacity for increased demand from daily operation of the plant. The city’s specification required that the gas holder be designed for an initial operating pressure of 6½ inches water column and to be able to accommodate an increased future operating pressure of 14 inches water column. The piston deck was designed to accommodate the future placement of additional ballast for the increased pressure. |

|

STI/SPFA 2014 TANK OF THE YEAR Product Award -Reservoir

| Product / project title: | Initial Expansion of the Groundwater Replenishment System – (2) 7.9 MG Equalization Tanks |

| Product / project owner: | Orange County Water District |

| Product / project location: | Fountain Hills, CA |

| Date completed: | October 2014 |

| Construction standard (if any): | D100-05 |

| Overall height / length (feet, inches): | 32’ -0” |

| Column height (feet, inches): | – |

| Diameter (feet, inches): | 216’ -0” |

| Capacity (US gallons): | 15,800,000 (7.9M each) |

| Steel tonnage used (US tons): | 1,380 |

| Steel thickness (inches): | 3/16 to 0.656” |

| Product/Project Description: | |

| Project scope included provided engineering, fabrication, erection and coating of two (2) 7.9 million gallon welded steel reservoirs. Foundation design for each tank required 449 concrete piles 60 to 65 feet deep, due to ground soil having extremely high liquefaction potential during a seismic event. | |

| The project takes highly treated wastewater and purifies it through a three-step process that includes micro-filtration, reverse osmosis and ultraviolet light with hydrogen peroxide and then uses it to recharge the groundwater basin. It is the world’s largest advanced water purification facility of its kind prior to this expansion project, producing up to 70 million gallons of new water every day. | |

| Each tank is 216 ft. diameter x 32 ft. shell height with a three bay roof structure. Construction of the two tanks utilized over 1,380 tons of steel. Both tanks were shop blasted and primed prior to field application of high performance 100% solids coating system on the full interior. It is estimated that the life-cycle of the tank coatings is 50 years. | |

STI/SPFA 2014 TANK OF THE YEAR Product Award -Shop Fabricated

| Product / project title: | Vineyards |

| Product / project owner: | PRIVATE |

| Product / project location: | St. Helena, CA |

| Date completed: | August 2014 |

| Construction standard (if any): | ASCE 7 |

| Overall height / length (feet, inches): | 31’ -0” |

| Column height (feet, inches): | 8’ -0” |

| Diameter (feet, inches): | 10’ -0” |

| Capacity (US gallons): | 12,300 |

| Steel tonnage used (US tons): | 9.5 |

| Steel thickness (inches): | 0.135 – 3/16” |

| Product/Project Description: | |

| In the process of producing red wine, extraction of color and tannins is a vital step. Under traditional winemaking procedures, this extraction is time consuming. A process developed in Europe, Flash Détente now allows the winemakers to extract the desirable compounds from the skins prior to fermentation, a step that reduces cycle time and increases product throughput. Flash Détente is the current version of the traditional thermovinification method. In this method, the crushed and de-stemmed grapes are rapidly heated to around 180°F, then the heated grapes are processed in a vacuum flash cooling system where the temperature is rapidly lowered to 86°F. The rapid cooling sequence causes an intercellular explosion in grape skins that produces the desired color and characteristics in an improvement over the traditional thermovinification method. | |

| In order to process grapes in the Flash Détente process, the grapes must be processed in a mixer tank capable of maintaining a homogeneous gelatinous emulsion of the juice and solids. This tank was specially designed to accommodate a high torque, low speed internal mixer. To interface with existing winery equipment, this tank was required to be mounted on legs at 8 feet above the floor. | |

| The tank is located in a region subject to high seismic loads, so a substantial foundation, anchorage and support structure was required to resist the ASCE 7 design loads. Additionally, the tank must support the substantial mixer loads, both gravity and torque loads. The support of the mixer and mixer shaft required close tolerance fabrication of the mixer support structure and guides. The tank is constructed entirely of Type 304 stainless steel. | |

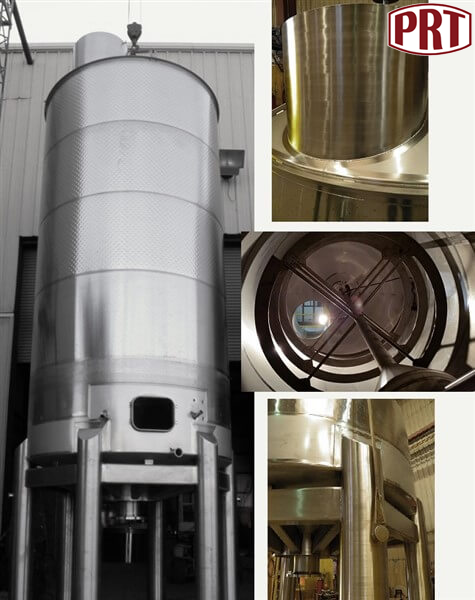

STI/SPFA 2013 TANK OF THE YEAR Product Award

Bridge District Illuminated Tank

This 3.3 MG was planned and designed to meet the needs of the expanding developments around the “Bridge District” of West Sacramento, CA.This tank is designed to be a green structure with the storage tank designed to accommodate future solar power system installation, including 1,104 solar panel brackets installed during initial tank construction.

Steel was selected as the material of choice even with the following extra cost factors included:

1. Full containment during blasting and painting operations due to proximity of residential neighborhood.

2. The exterior of the tank was coated with High Performance Coatings (Urethane Gloss Enamel) to assist with the specialty lighting scheme.

There were 500 tons of steel used in the tank and the foundation. The tank was designed per section 14 of AWWA. The owner required 1/8″ corrosion allowance due to the location of the tank and the marine environment. The roof plate was designed at a thickness of 5/16″, which increased the size of the roof structure and supports.

The combination of architectural features, painting scheme and nighttime lighting have, created a new local landmark.

STI/SPFA 2013 TANK OF THE YEAR Product Award (2nd)

E&J Gallo Winery Expansion

Design, fabricate and field erect (16) 350,000 gallon light gage stainless steel wine storage tanks with dimple style refrigeration jackets.

Due to the short construction schedule required to meet project requirements, the tanks were erected in the field using panelized construction. Providing over 5,600,000 gallons of additional storage capacity, these 16 tanks required over 20,000 parts and pieces totaling more than 1,040,000 pounds of stainless steel.

To meet the rigid customer specifications, achieve the performance requirements on the refrigeration jackets, and accommodate the butterfly foundations, this project required our company to develop new fabrication, erection and welding techniques.

STI/SPFA 2013 TANK OF THE YEAR Product Award (3rd)

Desert Water Fabrication

Desert Water Agency processes secondary effluent from the Palm Springs Waste Water Treatment Plant into recycled effluent water that is used at all the public golf courses in Palm Springs.

During normal operations, the influent reservoirs collect several inches of sediment on the reservoir floors. This can create turbidity spikes requiring more chemical dosage during the filtration process, and can clog the filters much faster than normal, preventing the Agency from producing the recycled effluent water for its customers. Influent Reservoir No. 1 was not designed for annual floor cleaning.

The Agency had considered demolishing their existing steel reservoir and replacing with concrete reservoir. Once they evaluated the cost they decided to save their existing steel reservoir and remove the roof to install a new cleaning system that will save water, reduce the amount of chemical dosing, and get the reclaimed water out to the end user in a timely fashion.

The walkway’s and handrail were fabricated complete in our fabrication facility with galvanized structural steel and anodized aluminum handrail. There was a total of 800 feet of aluminum pipe that was welded together and anodized. The Walkway’s were then delivered and installed over the existing tank to allow for access for the water cannon cleaning system.